About Sealed Air Corporation

Sealed Air Corporation (SEE) is a leading packaging solutions provider with headquarters in Charlotte, North Carolina. Sealed Air provides custom packaging solutions for the world’s top brands.

Invonto has been our trusted development partner since 2014. We hired them for automating processes for our product care division. Over the years, they have built many cloud, mobile, and IoT applications transforming our processes and contributing to our success. They often stepped into helping us with critical needs. We’ve formed a great partnership with the Invonto team and highly recommend them to anyone looking for a reliable tech team.

Matt Thompson

Executive Director – Packaging Technology, Sealed Air

Challenge

Sealed Air product care division operated on legacy systems and processes making their business operations slow, expensive, and less competitive.

Some of their challenges included:

- Sales representatives manually gathered specifications for the products needing packaging solutions using paper forms

- Designers were preparing packaging solutions using software but did not have a way to share that with customers

- Technical expertise and capabilities were not shared across their entire business causing inconsistencies and duplication of work

- Customers and trade partners were not able to contribute

- Lack of management oversight on business performance and trends

To overcome these challenges, we wanted to build a custom digital solution to transform Sealed Air packaging offerings.

Objectives

Digital Transformation | Process Automation | Enterprise Mobility | Revenue Growth

Process

When we met with Sealed Air, our idea was to build a mobile application for their sales and account reps. They did not have defined digital strategies or goals. Our team gathered detailed requirements from onsite working sessions. Those discoveries led to developing long term digital strategies, creating a product roadmap, and defining digital solutions required to meet their business objectives and goals. Initially, Sealed Air wanted to develop a mobile application, however, their ultimate need was to create a suite of products covering multiple use cases in their packaging processes.

Invonto developed a unique digital solution for each use case following agile development best practices. To maintain full transparency on development status, solutions were built in conjunction with Sealed Air employees. On completing each milestone, we reviewed progress with Sealed Air and released updates to end users following standard devops processes. We delivered each solution on time and within budget to meet client expectations.

Tech Stack:

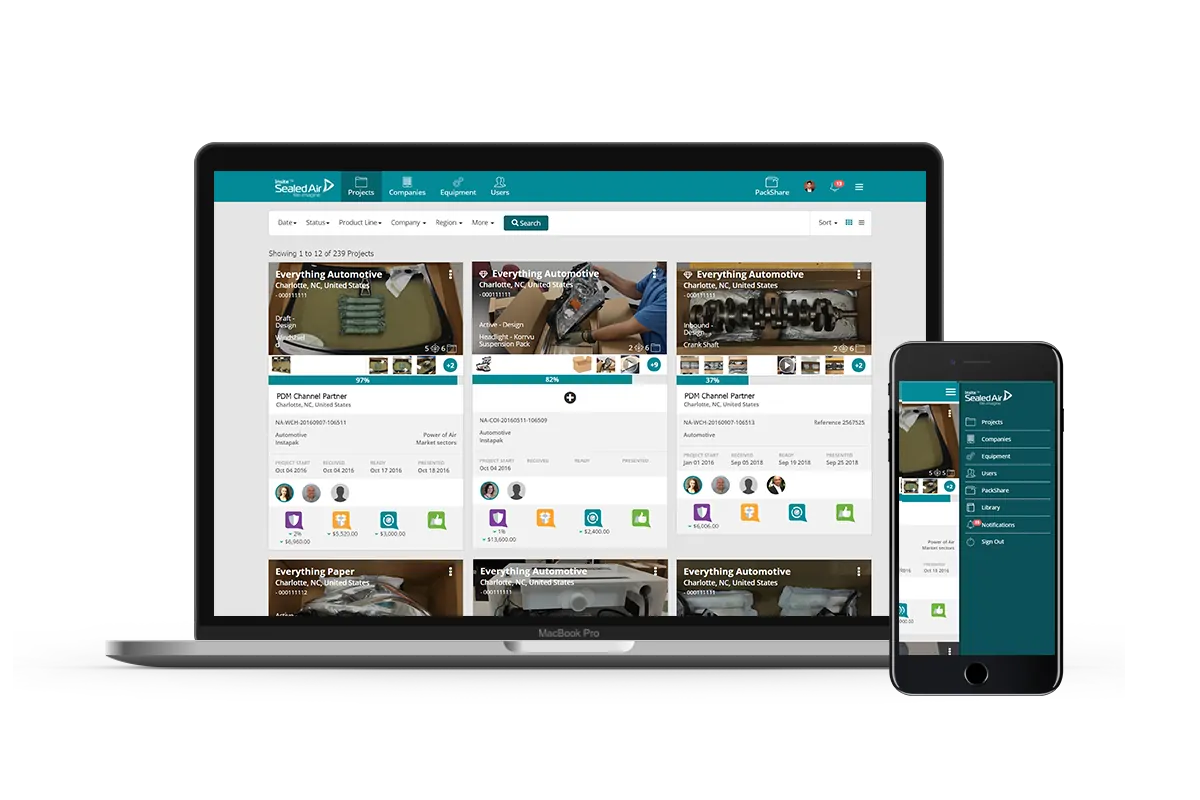

Solution #1: Project Management Application

The Sealed Air product care division needed to improve how they gathered product specifications from customers. In addition, they needed to efficiently design custom packaging solutions according to the customer’s feedback. We designed and developed a cloud-based project management application, called Insights, hosted on the AWS infrastructure accompanied by a mobile app. This application streamlined Sealed Air packaging design process and brought consistency to the workflow of sales reps and designers across the globe. As part of the solution requirement, we built API interfaces with SAP ERP and CRM systems as well as built a developer API for Sealed Air’s reporting, design, and analytics platforms.

Key Functions:

Security

User login and role management

Design Projects

Creating and managing packaging design projects

Contact Management

Manage customer company and contact data

Equipment Overview

Manage equipment system details

Media Upload

Ability to upload and view photos & videos

Packaging Instructions

Ability to setup step-by-step instructions for packaging solutions

PDF Export

Ability to export data into pdf format

Localization Support

Multi-lingual support for global users

Notifications

Email notifications and messaging capabilities

KPI Reports

Analytics tracking for monitoring application usage

Knowledge Rating Systems

Intelligence-driven knowledge rating systems

Sustainability Calculator

Sustainability calculator for measuring the reduction in carbon footprint

Barcode and QR

Ability to scan barcode and QR Codes

API Integration

API Integration with ERP, CRM, Reporting, Analytics, and Design systems

PDF Export

Ability to export data into pdf format

Localization Support

Multi-lingual support for global users

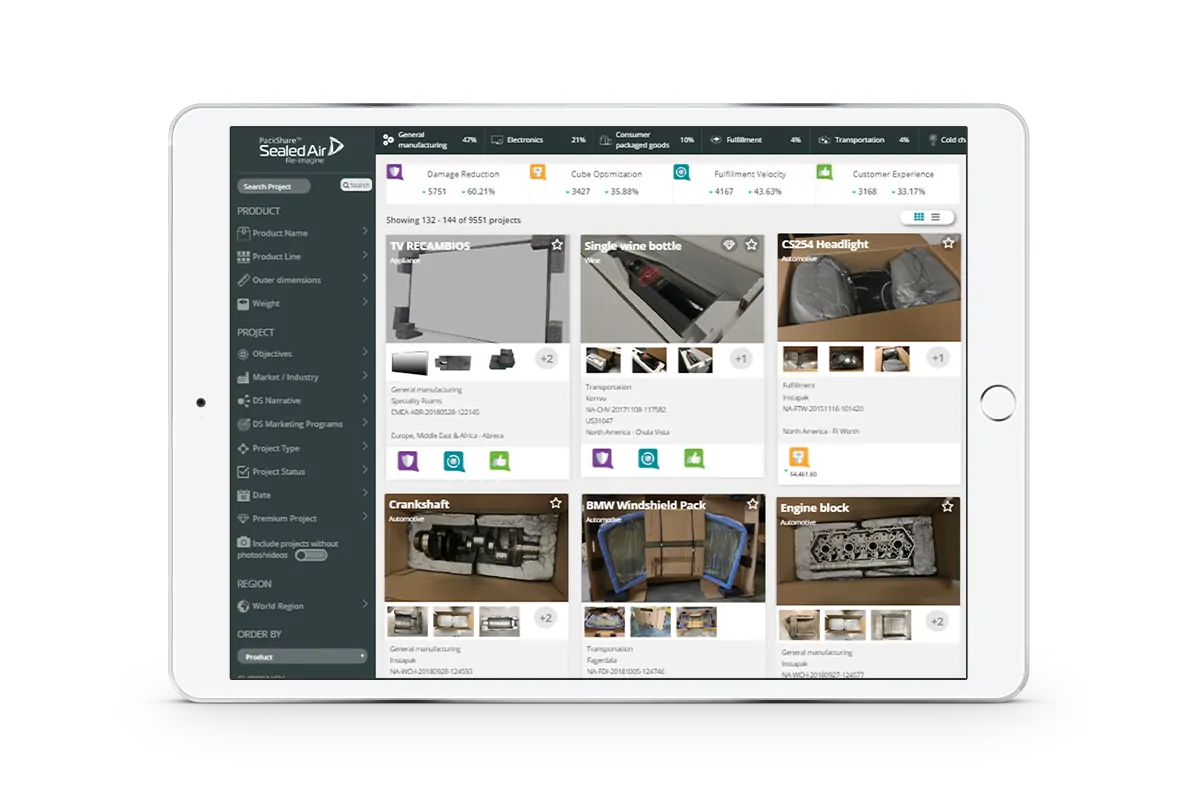

Solution #2: Knowledge Sharing Platform

After Sealed Air’s team started using the newly launched project management application, they were quickly and efficiently able to document thousands of projects. The early success paved a way for the next digital solution, PackShare, which allowed designers, reps, and trade partners to have access to data of all Sealed Air projects. Invonto designed and developed an AI / machine learning solution that allowed users to perform context-based research on packaging design projects, gain insights from the prior design solutions, and use a recommendation engine for initiating new packaging design projects. This platform also served as a pitch deck/sales platform allowing sales & account reps to find relevant projects for new customers using preference based and personalized searches. This solution improved 40% efficiency in new packaging designs and 22% increase in conversion rate.

Key Functions:

Security

User login and role management

Personalization

Personalized features based on user preferences

Preference-based Search

Search & filter Packaging design projects

Localization Support

Allowing searches in all languages with Google Translation

Data Analytics

Advanced data insights for recommendations and trend forecasting

Explore Designs

Ability to view best matching packaging solution designs

Single Page Responsive Application

Supporting desktop and tablet users

API Integration

API Integration for data, personalization, and analytics

Solution #3: Customer Portal with IoT capabilities

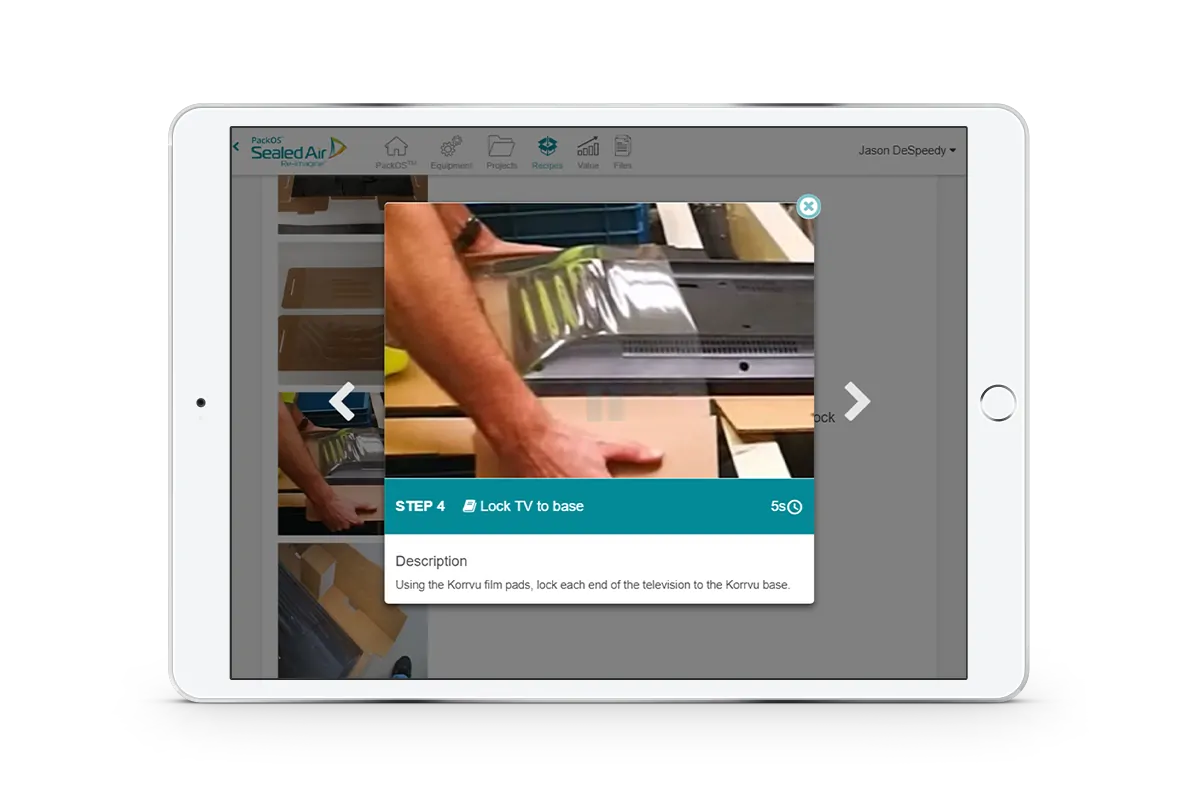

Sealed Air identified a need for their customers to have a solution that helps them effectively manage their own packaging processes; improving productivity and reducing damage. To meet this need, Invonto designed a cloud-based solution and a tablet application for the technicians to run the packaging process in front of an equipment. This solution, called PackOS, included step-by-step instructions with photos and videos to walk a packer through the packaging process for all of the customer’s products. This solution helped customers make packaging processes more efficient and precise, reducing waste.

Key Functions:

Security

User login and role management

Automate Packing Process

Automate packing process on packaging equipment

Localization Support

Support multiple languages, UOMs, and currencies

Barcode Scanning

Ability to view packaging solution designs

Manage Files

Manage company file attachments

Equipment Management

Monitor and manage packaging equipment remotely

Export Data

Ability to Export Data in CSV and PDF

Packing Instructions

Ability to setup multiple packing instructions

API Integration

API Integration for Data, Reporting, and Equipment Monitoring

Single Page Responsive Application

Supporting desktop and tablet users

Solution #4: KPI Dashboard Application

New digital solutions supercharged Sealed Air’s packaging portfolio with an average of 14,000 new packaging design projects each year. Their management team needed to analyze key-performance-indicators to set business directions & goals. Invonto helped meet this need by designing & developing a KPI dashboard application.

Key Functions:

Data Analysis

Data analysis and aggregation for multiple KPI categories

Heat Map

Heat map view highlighting top performing locations

Real-time KPIs

Visualizing Key Performance Indicators

Trend Forecasting

Displaying trends by industry to identify growth sectors

Regional Stats

Recognizing top sales rep, account rep, and packaging designer in each region

Identify Value

Identifying business value delivered to customers for damage reduction, space optimization, and customer satisfaction

Solution #5: Packaging Sustainability Solution

Sealed Air is committed towards sustainability and improving our environment. Sealed Air is achieving this by delivering innovative and sustainable packaging solutions that address environmental impact and reduce waste. In 2015, Sealed Air announced their sustainability goals for 2025. As part of the initiatives to measure progress towards Sealed Air’s sustainability goals, we built a Damage Footprint Calculator. This application allows users to calculate packaging waste reductions based on the reduction in damage rate. This enables Sealed Air to see how a particular packaging solution not only reduces costs, but reduces the overall carbon footprint.

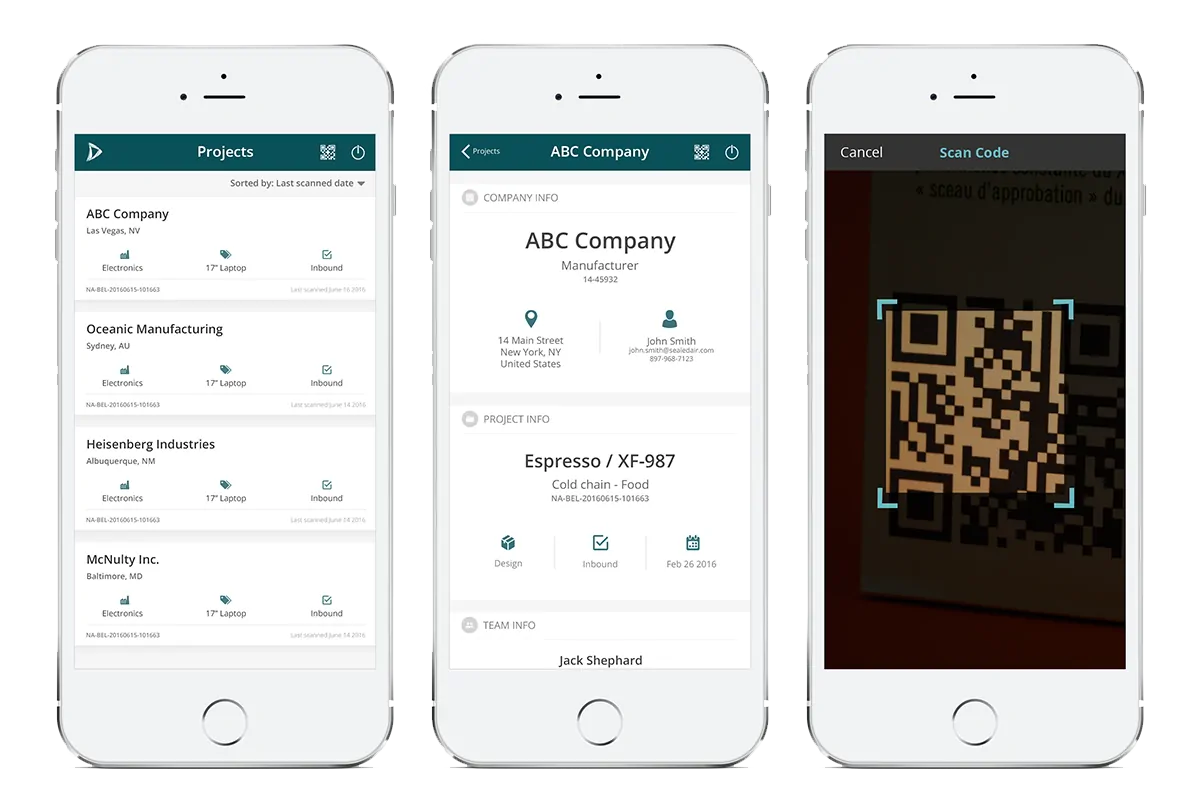

Solution #6: Mobile Application with QR scanning

One of the common challenge faced by all businesses is traceability and timely access to data. One of the challenges Sealed Air’s business faced was not being able to identify specific packaging solution used for a product packaging. To overcome this, we built a mobile app with the QR scan capability. By using this app, users are able to retrieve key details of the packaging solution as well as generate data that helped analyze root causes for the damaged packages.

Key Functions:

Security

User login

Scan QR Codes

Ability to scan QR code

Packaging Details

Viewing packaging details

Issue Tracing

Ability to track packaging issues based on product damages

Notifications

Generating notifications for data reporting

Localization

Multi-lingual support

Results

Each new digital solution helped Sealed Air transform their business operations to become an industry disruptor. Collaboration amongst field reps, packaging designers, customers, and trade partners improved significantly. With improvised business processes and digital tools, Sealed Air Corporation sales grew substantially providing a high ROI on their digital investment. Some of the solutions grew to become revenue-generating products. All solutions were completed over 4.5 years and required a total investment of $3.75M.

Services Offered

![]()

Digital Strategy

![]()

UI / UX Design

![]()

Product Management

![]()

Web Development

![]()

Mobile Application Development

![]()

QA Testing

![]()

DevOps

![]()

Application Support

![]()

Legacy Application Migration

READY TO GET STARTED?